Through constant modernisations, LÜBERG ELEKTRONIK is able to keep up with the rapid pace of technical development. The production facilities of LÜBERG ELEKTRONIK are unique in Europe. As the “biggest supplier of printed circuit boards”, LÜBERG ELEKTRONIK manufactures large-format printed circuit boards (PCB) on specially-designed machines. For a higher functional density and miniaturisation of its components, LÜBERG ELEKTRONIK offers Flex-PCB and 3D-MID technology. We also find suitable solutions for your special sizes and configurations.

LÜBERG ELEKTRONIK manufactures printed circuit boards (PCB, Flex-PCB), special printed circuit boards, mechatronic components (3D-MIDs), metallised plastic parts and precision contour-etched parts on a production area of 6,000 square metres. Automated processes and production methods ensure consistently top quality, from the prototype to the series product. The new internal laboratory guarantees the latest standards in the fields of process optimisation and quality. Quick and reliable delivery times ensure cost-effective and on-schedule processing. We manufacture in small and medium series with a convincing price-performance ratio, including special formats and over-sizes.

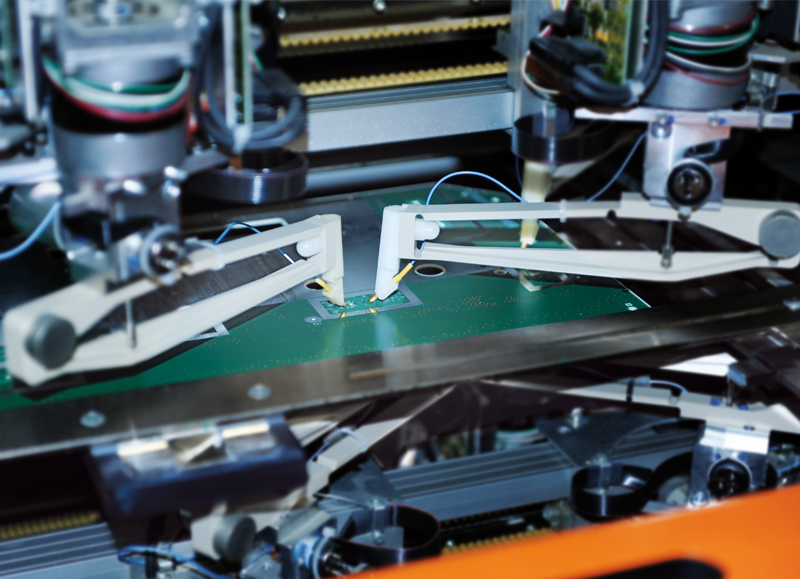

Our production hall contains the following equipment:

With the help of a laser direct exposure unit, the blanks are exposed with the highest precision.

For the mechanical processing of oversized printed circuit boards with a length of 1.40 metres

We offer the electrical testing of the printed circuit board with the use of a flying-probe (finger tester). Further information about our comprehensive quality management is available here.